PWE 2 - DOUBLE PREP AREA SEMI-DOWNDRAFT OR CROSSDRAFT

Eccellente

★ Trustpilot

★

★

★

★

★

4.6

● Available

Code: Two Prep Window Bay

EAN:

PICTURES

VIDEOS

DETAILS

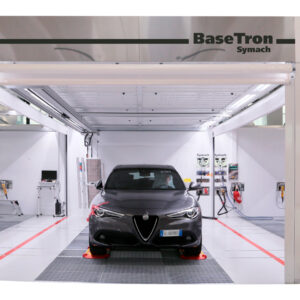

Double Prep Area – PWE 2 – Semi-downdraft or cross-draft

THIS PRODUCT REQUIRES CONFIGURATION

The basic configuration includes:

- Double rear extraction wall with a ventilation grid

- One shared ventilation group with a 7.5 kW – 10 HP fan

- Automatic air changing preparation bay during the spraying phase

- Control box, PC, Touch screen 7″, inverter

To complete the configuration, you can choose:

- Double ceiling plenums, with or without intake air

- The burner

- The sides may feature a double-skin insulated metal panel or an electric or manual curtain.

- The front may have an electric or manual curtain

- The floor may have a reinforced grid for commercial vehicles

The Prep Window Bay is a double-preparation area with a cross-draft. It is suitable when a downdraft is not possible; extraction occurs entirely through the grille on the front wall.

It has fans with independent inverters and two 7″ touch screens for autonomous management.

It ensures the removal of sprayed paint and sanding dust during vehicle preparation.

The machine can be configured with accessories that transform it from a simple suction wall to a paint booth.

The electric curtains and the Flydry robotic drying system are shared; a single system can have tracks in both areas, allowing drying in both zones.

PWB-B2 features a mini-computer and a 7-inch touchscreen, automating extraction during spraying and drying.

The program automatically recognizes the painting and drying phases, adjusts the ventilation speed accordingly, and closes the ventilation system at the end of spraying.

The advantage of this automated program is reduced energy consumption since the machine only operates when necessary.

| TECHNICAL DATA | |||

|---|---|---|---|

| MANAGEMENT AND CONTROL SYSTEM | |||

| MiniPC | RASPBERRY | ||

| Touch screen | 10" HD | ||

| OPTION | Intake inverter | 7.5 Kw *2 | 10 HP *2 |

| Exaust inverter | 7.5 Kw *2 | 10 HP *2 | |

| Internal temperature probe | YES | ||

| CONFIGURABLE WORK PROGRAMS | |||

| Spraying | Independent program per bay | ||

| Drying | Independent program per bay | ||

| PREPARATION BAY SIZE | |||

| Internal length | 8.0 m. | 26.25 Ft. | |

| External length | 8.2 m. | 26.9 Ft. | |

| Internal width | 4.5 m. | 14.76 Ft. | |

| External width | 4.7 m. | 15.42 Ft. | |

| Internal height | 3.0 m. | 9.84 Ft. | |

| External height | 3.7 m. | 12.14 Ft. | |

| OPTION | Internal height | 3.5 m. | 11.48 Ft. |

| OPTION | External height | 4.2 m. | 13.78 Ft. |

| VENTILATION GROUP (For every bay) | |||

| Length | 2.0 m. | 6.56 Ft. | |

| Width | 1.3 m. | 4.27 Ft. | |

| Space needed for filter changes | 0.7 m. | 2.30 Ft. | |

| Rear positioning | YES | ||

| Side positioning | YES | ||

| OPTION | Intake motor | 7.5 Kw *2 | 10 HP *2 |

| Exhaust motor | 7.5 Kw *2 | 10 HP *2 | |

| OPTION | Intake fan | 24.000 mc/h *2 | 14.150 CFM *2 |

| Exhaust fan | 24.000 mc/h *2 | 14.150 CFM *2 | |

| BURNER (Per bay) | |||

| OPTION | Burner *2 | 300 Kw | 1.100.000 BTU |

| Fuel | NATURAL GAS - LPG | ||

| LIGHT STRIP LED (For every bay) | |||

| Color fidelity | 0.94 CRI | ||

| Color Temperature | 5.555 Kelvin | ||

| POWERLed 2 rows on the Right and Left *2 | 800 Lux | 74 Ft. Candle | |

| MANUFACTURING | mm. | Gauge | |

| Sandwich panels wall mm 50 pre-painted white. | 1.2 | 16 | |

| Galvanized sheet metal frame | 2.0 | 12 | |

| Galvanized sheet metal ducts | 1.0 | 18 | |

| Ventilation group galvanized sheet metal | 3.0 | 8 | |

| Stainless steel finishes | 1.0 | 18 | |

| FILTERS (for every bay) | mq | sq. ft. | |

| Plenum filter | 26.0 *2 | 279.8 *2 | |

| Poket filter Intake and exaust | 12.0 *2 | 129.2 *2 |

PWE 2 – DOUBLE PREP AREA SEMI-DOWNDRAFT OR CROSSDRAFT

Prezzo: $21,060.00

Double Prep Area – PWE 2 – Semi-downdraft or cross-draft

THIS PRODUCT REQUIRES CONFIGURATION

The basic configuration includes:

- Double rear extraction wall with a ventilation grid

- One shared ventilation group with a 7.5 kW – 10 HP fan

- Automatic air changing preparation bay during the spraying phase

- Control box, PC, Touch screen 7″, inverter

To complete the configuration, you can choose:

- Double ceiling plenums, with or without intake air

- The burner

- The sides may feature a double-skin insulated metal panel or an electric or manual curtain.

- The front may have an electric or manual curtain

- The floor may have a reinforced grid for commercial vehicles

The Prep Window Bay is a double-preparation area with a cross-draft. It is suitable when a downdraft is not possible; extraction occurs entirely through the grille on the front wall.

It has fans with independent inverters and two 7″ touch screens for autonomous management.

It ensures the removal of sprayed paint and sanding dust during vehicle preparation.

The machine can be configured with accessories that transform it from a simple suction wall to a paint booth.

The electric curtains and the Flydry robotic drying system are shared; a single system can have tracks in both areas, allowing drying in both zones.

PWB-B2 features a mini-computer and a 7-inch touchscreen, automating extraction during spraying and drying.

The program automatically recognizes the painting and drying phases, adjusts the ventilation speed accordingly, and closes the ventilation system at the end of spraying.

The advantage of this automated program is reduced energy consumption since the machine only operates when necessary.

| TECHNICAL DATA | |||

|---|---|---|---|

| MANAGEMENT AND CONTROL SYSTEM | |||

| MiniPC | RASPBERRY | ||

| Touch screen | 10" HD | ||

| OPTION | Intake inverter | 7.5 Kw *2 | 10 HP *2 |

| Exaust inverter | 7.5 Kw *2 | 10 HP *2 | |

| Internal temperature probe | YES | ||

| CONFIGURABLE WORK PROGRAMS | |||

| Spraying | Independent program per bay | ||

| Drying | Independent program per bay | ||

| PREPARATION BAY SIZE | |||

| Internal length | 8.0 m. | 26.25 Ft. | |

| External length | 8.2 m. | 26.9 Ft. | |

| Internal width | 4.5 m. | 14.76 Ft. | |

| External width | 4.7 m. | 15.42 Ft. | |

| Internal height | 3.0 m. | 9.84 Ft. | |

| External height | 3.7 m. | 12.14 Ft. | |

| OPTION | Internal height | 3.5 m. | 11.48 Ft. |

| OPTION | External height | 4.2 m. | 13.78 Ft. |

| VENTILATION GROUP (For every bay) | |||

| Length | 2.0 m. | 6.56 Ft. | |

| Width | 1.3 m. | 4.27 Ft. | |

| Space needed for filter changes | 0.7 m. | 2.30 Ft. | |

| Rear positioning | YES | ||

| Side positioning | YES | ||

| OPTION | Intake motor | 7.5 Kw *2 | 10 HP *2 |

| Exhaust motor | 7.5 Kw *2 | 10 HP *2 | |

| OPTION | Intake fan | 24.000 mc/h *2 | 14.150 CFM *2 |

| Exhaust fan | 24.000 mc/h *2 | 14.150 CFM *2 | |

| BURNER (Per bay) | |||

| OPTION | Burner *2 | 300 Kw | 1.100.000 BTU |

| Fuel | NATURAL GAS - LPG | ||

| LIGHT STRIP LED (For every bay) | |||

| Color fidelity | 0.94 CRI | ||

| Color Temperature | 5.555 Kelvin | ||

| POWERLed 2 rows on the Right and Left *2 | 800 Lux | 74 Ft. Candle | |

| MANUFACTURING | mm. | Gauge | |

| Sandwich panels wall mm 50 pre-painted white. | 1.2 | 16 | |

| Galvanized sheet metal frame | 2.0 | 12 | |

| Galvanized sheet metal ducts | 1.0 | 18 | |

| Ventilation group galvanized sheet metal | 3.0 | 8 | |

| Stainless steel finishes | 1.0 | 18 | |

| FILTERS (for every bay) | mq | sq. ft. | |

| Plenum filter | 26.0 *2 | 279.8 *2 | |

| Poket filter Intake and exaust | 12.0 *2 | 129.2 *2 |

| ID | Name | Roll |

|---|

Related Products

In total

$21,060.00