PICTURES

VIDEOS

DETAILS

DryBox 25

It is a small infrared oven used to dry the disassembled parts of a car, such as bumpers, fenders, and doors.

It is an excellent solution to lighten the drying activity in the paint booth.

Drying is performed using Drytronic infrared technology, which ensures a drying time of less than 50% compared to traditional paint booths.

Additionally, the drying cost is less than 10% of that of a traditional paint booth.

| DRYING TIME COMPARED CLASSIC PAINT BOOTH | IR DRYBOX | CLASSIC SPRAY BOOTH |

|---|---|---|

| Primer | 0:10 minutes | 0:30 minutes |

| Clear Coat drying time | 0:15 minutes | 0:30 minutes |

| Drying | Multiple program configurable |

| TECHNICAL DATA | ||

|---|---|---|

| MANAGEMENT AND CONTROL SYSTEM | ||

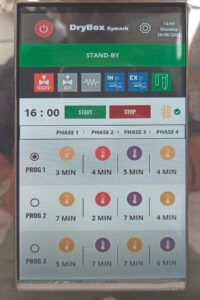

| MiniPC | RASPBERRY | |

| Touch screen | 7" HD | |

| DRYING CABIN MEASURE | METER | FEET |

| Internal length | 2,00 | 6,56 |

| External length | 2,20 | 7,22 |

| Internal width | 4,00 | 13,12 |

| External width | 4,20 | 13,78 |

| Internal height | 2,90 | 9,51 |

| External height | 3,30 | 10,83 |

| VENTILATION GROUP ON THE ROOF | METER | FEET |

| Rear positioning | YES | YES |

| Side positioning | YES | YES |

| Intake motor | 0.37 Kw | 0.5 HP |

| Extraction motor | 0.37 Kw | 0.5 HP |

| Intake fan | 1.200 mc/h | 700 CFM |

| Exhaust fan | 1.200 mc/h | 700 CFM |

| INFRARED CATHALYTIC | ||

| Number of catalytic panels in line | 2 | |

| Lenght of the panel | m. 0.90 | ft. 2.95 |

| Panel widht | m. 0.50 | ft. 1.64 |

| Power generated | 34 Kw | 120.000 BTU |

| NATURAL GAS | 3.4 mc/h | 2.0 CFM |

| LPG | 1.7 kg/h | 3.7 lb/h |

| MANUFACTURING | mm. | Gauge |

| Stainless steel floor | 1.0 | 18 |

| Sandwich panels wall mm 50 pre-painted white external stainless steel internal | 1.2 | 16 |

| Stainless steel ceiling | 1.0 | 18 |

| Galvanized sheet metal ducts | 1.0 | 18 |

| Ventilation group galvanized sheet metal | 3.0 | 8 |

| Door | m. 2.0 X H 2.0 | ft. 6.6 X 6.6 |

DryBox

Price: $27,900.00

DryBox 25

It is a small infrared oven used to dry the disassembled parts of a car, such as bumpers, fenders, and doors.

It is an excellent solution to lighten the drying activity in the paint booth.

Drying is performed using Drytronic infrared technology, which ensures a drying time of less than 50% compared to traditional paint booths.

Additionally, the drying cost is less than 10% of that of a traditional paint booth.

| DRYING TIME COMPARED CLASSIC PAINT BOOTH | IR DRYBOX | CLASSIC SPRAY BOOTH |

|---|---|---|

| Primer | 0:10 minutes | 0:30 minutes |

| Clear Coat drying time | 0:15 minutes | 0:30 minutes |

| Drying | Multiple program configurable |

| TECHNICAL DATA | ||

|---|---|---|

| MANAGEMENT AND CONTROL SYSTEM | ||

| MiniPC | RASPBERRY | |

| Touch screen | 7" HD | |

| DRYING CABIN MEASURE | METER | FEET |

| Internal length | 2,00 | 6,56 |

| External length | 2,20 | 7,22 |

| Internal width | 4,00 | 13,12 |

| External width | 4,20 | 13,78 |

| Internal height | 2,90 | 9,51 |

| External height | 3,30 | 10,83 |

| VENTILATION GROUP ON THE ROOF | METER | FEET |

| Rear positioning | YES | YES |

| Side positioning | YES | YES |

| Intake motor | 0.37 Kw | 0.5 HP |

| Extraction motor | 0.37 Kw | 0.5 HP |

| Intake fan | 1.200 mc/h | 700 CFM |

| Exhaust fan | 1.200 mc/h | 700 CFM |

| INFRARED CATHALYTIC | ||

| Number of catalytic panels in line | 2 | |

| Lenght of the panel | m. 0.90 | ft. 2.95 |

| Panel widht | m. 0.50 | ft. 1.64 |

| Power generated | 34 Kw | 120.000 BTU |

| NATURAL GAS | 3.4 mc/h | 2.0 CFM |

| LPG | 1.7 kg/h | 3.7 lb/h |

| MANUFACTURING | mm. | Gauge |

| Stainless steel floor | 1.0 | 18 |

| Sandwich panels wall mm 50 pre-painted white external stainless steel internal | 1.2 | 16 |

| Stainless steel ceiling | 1.0 | 18 |

| Galvanized sheet metal ducts | 1.0 | 18 |

| Ventilation group galvanized sheet metal | 3.0 | 8 |

| Door | m. 2.0 X H 2.0 | ft. 6.6 X 6.6 |

OPTIONALS

Related Products

In total

$27,900.00