DK-Kombi Driving through

Eccellente

★ Trustpilot

★

★

★

★

★

4.6

● Available

Code: DKKomby Driving through

EAN:

PICTURES

VIDEOS

DETAILS

DK-Kombi Driving through

The DryKing- Kombi Driving Through is a solution for the high-volume production of commercial vehicles. It allows for organizing the painting preparation and finishing phases in line.

An integrated CarMover dolly solution enables a single person to move the vehicle between various repair phases effortlessly and in just a few seconds.

Except for the layout, the technical characteristics are the same as those reported in the standard DK Kombi product.

| PERFORMANCE DATA DRYKING KOMBI | ||

|---|---|---|

| DRYING TIME COMPARISON | DRYKING | CLASSIC PAINT BOOTH |

| Waterborne drying time | 0:08 minutes | 0:30 minutes |

| Clear coat DryKing drying time | 0:20 minutes | 0:30 minutes |

| KOMBI | ||

| Cler coat IR Kombi drying tme | 00:15 | 00:30 minutes |

| PERFORANCE DATA | ||

| Waterborne drying time | 0:08 minutes | 0:30 minutes |

| Clear coat drying time | 0:20 minutes | 0:30 minutes |

| MANAGEMENT AND CONTROL SYSTEM | ||

| PLC | B&R | |

| Touch screen | 15" Ultra HD | |

| Intake inverter | 11 kW - 15 HP | |

| Exahust inverter | 11 kW - 15 HP | |

| Internal temperature thermostat | YES | |

| External temperature thermostat | YES | |

| External humidity detector | YES | |

| Intake pressure sensor | YES | |

| Extraction pressure sensor | YES | |

| Intake pocket filter clogging sensor | YES | |

| Extraction pocket filter clogging sensor | YES | |

| CUSTOMIZABLE CONFIGURATION | ||

| Drying program WET ON WET SEALER | Configurable drying program | |

| Dring program WATERBORNE | Configurable drying program | |

| Drying program CLEAR | Multiple configurable program | |

| Colling down program | Automatic with configurable time | |

| Spraying program | Ventilation with automatic activation and shutdown | |

| Stand-buy program between various work phases | Automatic start and stop | |

| SELF-DIAGNOSIS AND MAINTENANCE AND CONFIGURATIONS | ||

| Manage its maintenance activity with alarms and sending messages | ||

| Self-diagnosis in case of an anomaly with a tutorial for resolution | ||

| Configurable overpressure or underpressure painting | ||

| Automatic cabin shutdown at the end of the shift with configurable time | ||

| Remote assistance module via ethernet | ||

| Connection to the REMO portal for maintenance and usage tutorials and maintenance scheduler | ||

| From the REMO platform, records of the painting jobs to be done and those completed can be sent and received. |

| TECHNICAL DATA | |||

|---|---|---|---|

| DRYKING MEASURE | METER | FEET | |

| Internal length | 8,00 | 26,25 | |

| External length | 8,20 | 26,90 | |

| Internal width | 4,50 | 14,76 | |

| External width | 4,70 | 15,42 | |

| Internal height | 3,00 | 9,84 | |

| External height | 3,70 | 12,14 | |

| OPTION | Internal lengt | 10,00 | 32,81 |

| OPTION | External length | 10,20 | 33,47 |

| OPTION | Internal height | 3,50 | 11,48 |

| OPTION | External height | 4,20 | 13,78 |

| IR KOMBI MEASURE | METER | FEET | |

| Internal length | 8,00 | 26,25 | |

| External length | 8,20 | 26,90 | |

| Internal width | 4,50 | 14,76 | |

| External width | 4,70 | 15,42 | |

| Internal height | 3,00 | 9,84 | |

| External height | 3,70 | 12,14 | |

| DRYKING VENTILATION GROUP | |||

| Length | 4,00 m. | 13,12 ft. | |

| Width | 1,30 m. | 4,27 ft. | |

| Space needed for filter changes | 0,70 m. | 2,30 ft. | |

| Rear positioning | YES | YES | |

| Side positioning | YES | YES | |

| Intake motor | 11 Kw | 15 HP | |

| Extraction motor | 11 Kw | 15 HP | |

| Intake fan | 34.000 mc/h | 20.050 CFM | |

| Exhaust fan | 34.000 mc/h | 20.050 CFM | |

| IR KOMBI VENTILATION GROUP | |||

| Length | 2,00 m. | 6,56 ft. | |

| Width | 1,00 m. | 3,28 ft. | |

| Intake fan | 8.000 mc/h | 4.700 CFM | |

| Exhaust fan | 8.000 mc/h | 4.700 CFM | |

| DRYKING BURNER | |||

| Burner | 200 kW | 730.000 BTU | |

| OPTON | Burner | 300 kW | 1.100.000 BTU |

| FUEL | NATURAL GAS - LPG | ||

| IFRARED KOMBI | |||

| Number of cathalitic panel | 8 | ||

| Power generated | 136 Kw | 464.000 BTU | |

| FUEL | NATURAL GAS - LPG | ||

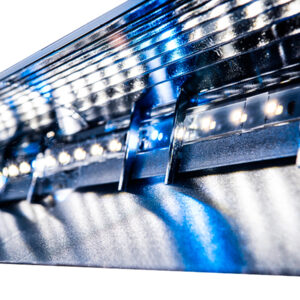

| LIGHT STRIP LED | |||

| Color fidelity | 0.94 CRI | ||

| Color Temperature | 5.555 Kelvin | ||

| POWERLed 3 rows on the Right and Left | 2.000 Lux | 185 Ft. Candle | |

| OPTION | 4 rows PowerLED on the Right and Left | 2.500 Lux | 230 Ft. Candle |

| DRYKING BASAMENT | |||

| Car floor grid | 700,00 kg. | 1.543,50 Lb. | |

| Option Commercial vehicle floor grid | 800,00 Kg. | 1.764,00 Lb. | |

| Floor with three rows of grids. | YES | YES | |

| OPTION | Floor with five rows of grids. | YES | YES |

| Pit depth | 0,65 m. | 2,13 ft. | |

| MANUFACTURING | mm. | Gauge | |

| Sandwich panels wall mm 50 - 2" pre-painted white. | 1.2 | 16 | |

| Galvanized sheet metal frame | 2.0 | 12 | |

| Galvanized sheet metal ducts | 1.0 | 18 | |

| Ventilation group galvanized sheet metal | 3.0 | 8 | |

| Stainless steel finishes | 1.0 | 18 | |

| DRYKING FILTERS | Sq. m. | Sq. ft. | |

| Plenum filter | 26.0 | 279.8 | |

| Paint stop floor filter 3 rows of grids | 20.0 | 215.3 | |

| OPTION | Paint stop floor filter 5 rows of grids | 35.0 | 376.7 |

| Poket filter Intake and exauste | 12.0 | 129.2 |