SPAP (Symach Paint Application Process) è il modo corretto di verniciare integrando l’uso della tecnologia Drytronic e il robot.

Drytronic è la tecnologia che essicca la vernice in pochi secondi, ciò ci ha permesso di sviluppare un processo di verniciatura che riduce totalmente i tempi di appassimento.

La qualità dell’essiccazione Drytronic è superiore a qualsiasi altra essiccazione fatta ad aria calda o infrarosso elettrico, perché la reticolazione è istantanea e totale al 100%, il prodotto verniciante risulta stabile e inerte che nessun difetto può affiorare in futuro. Consente inoltre una perfetta e immediata carteggiatura e lucidatura.

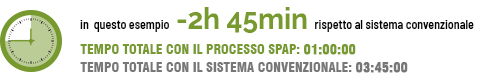

Il processo di applicazione ed essiccazione SPAP, sviluppato per tutti i prodotti vernicianti, per tutte le marche con formule di essiccazioni diverse nel rispetto della scheda tecnica del produttore. Il tempo di applicazione dei prodotti vernicianti si riduce del 60-70%, mentre il tempo di essicazione si riduce di un 80-90% rispetto a un sistema convenzionale.

Processo SPAP per Stucco, Fondo, Base all’acqua, Trasparente

Stucco: Il processo di applicazione ed essiccazione SPAP permette di finire la stuccatura in un’unica applicazione con compattezza e qualità superiore alla doppia applicazione utilizzata nel ciclo tradizionale, ma con meno di metà tempo e prodotto. Ad esempio l’applicazione ed essiccazione di una stuccatura eseguita in continuo senza interruzioni avviene in meno di cinque minuti.

Fondo: Il processo di applicazione del fondo avviene senza interruzione, perché l’appassimento tra mani è fatto dal robot, ad esempio l’applicazione ed essiccazione di tre mani di Fondo avviene in meno di otto minuti. La tecnologia Drytronic permette inoltre di applicare il fondo anche a rullo con tempi di applicazione, essiccazione e spessori identici a quella a spruzzo, ma risparmiando il 60% del prodotto verniciante e il 100% di materiale e tempo di mascheratura.

Base all’acqua: L’applicazione delle due o tre mani, in base alla marca, è consecutiva senza interruzione; ad esempio applicazione ed essiccazione di una riparazione di tre pannelli richiedono meno di sei minuti.

Trasparente: L’applicazione di due mani avviene consecutiva senza interruzioni; ad esempio applicazione ed essiccazione di una verniciatura di tre pannelli richiedono meno di dodici minuti.

Processo SPAP per DryTron

Il DryTron essica ogni marca e tipo di vernice in meno di un minuto e mezzo.

Stucco essica in 40 secondi

Fondo essica in 40 secondi

Base all’acqua essica in 50 secondi

Trasparente essica in 80 secondi

I tempi indicati possono variare in base alla marca, al tipo di vernice e al clima.

Processo SPAP per FixStation

La FixStation usa il FlyDry per essicare la vernice.

Stucco essica in 13 minuti

Fondo essica in 11 minuti

Base all’acqua essica in 9 minuti

Trasparente essica in 10 minuti