Drying Robot for Spraybooth

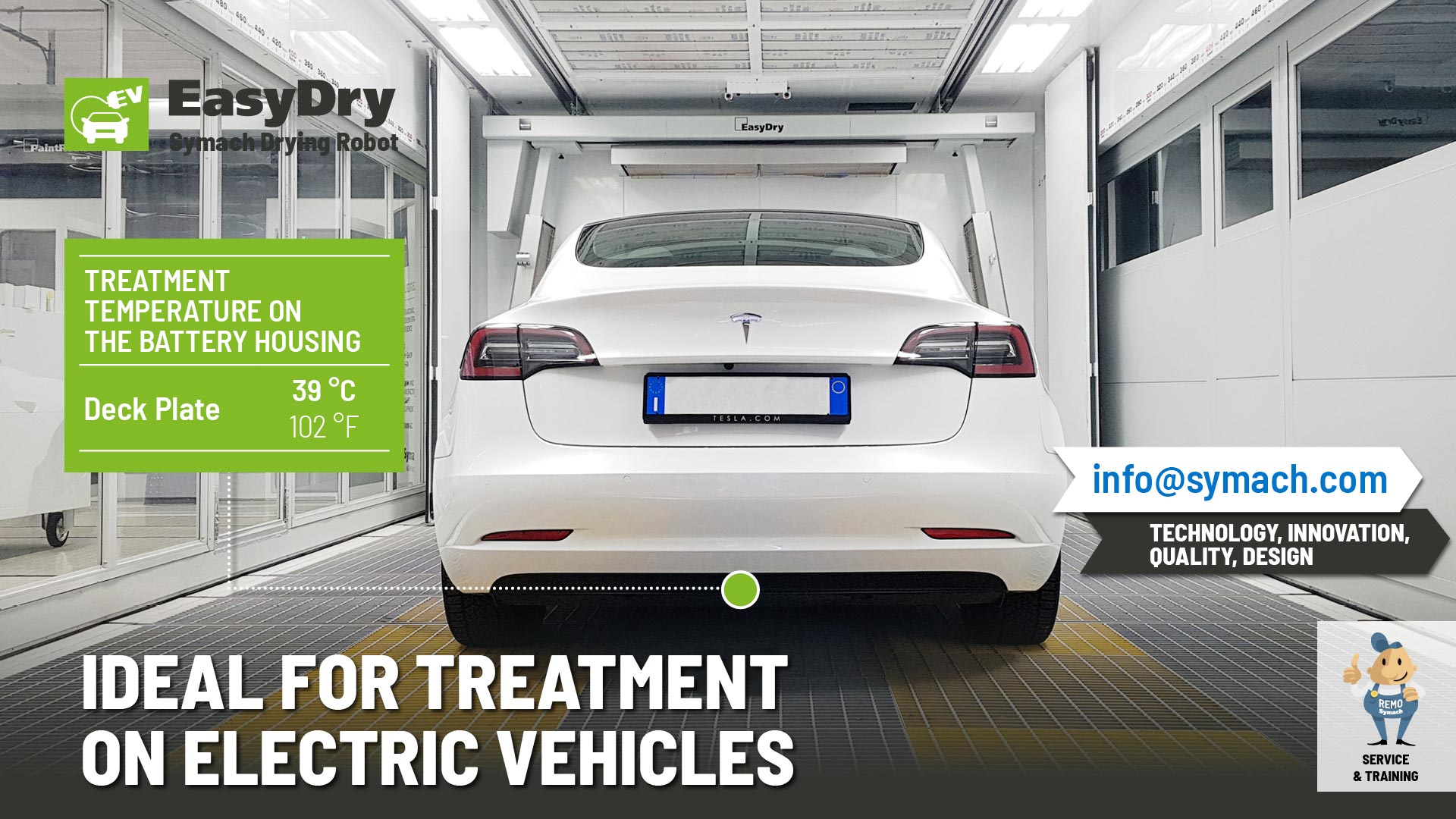

The EasyDry drying robot is specifically designed for spraybooth, to ensure comprehensive drying of all painted vehicle surfaces, including individual parts placed on stands.

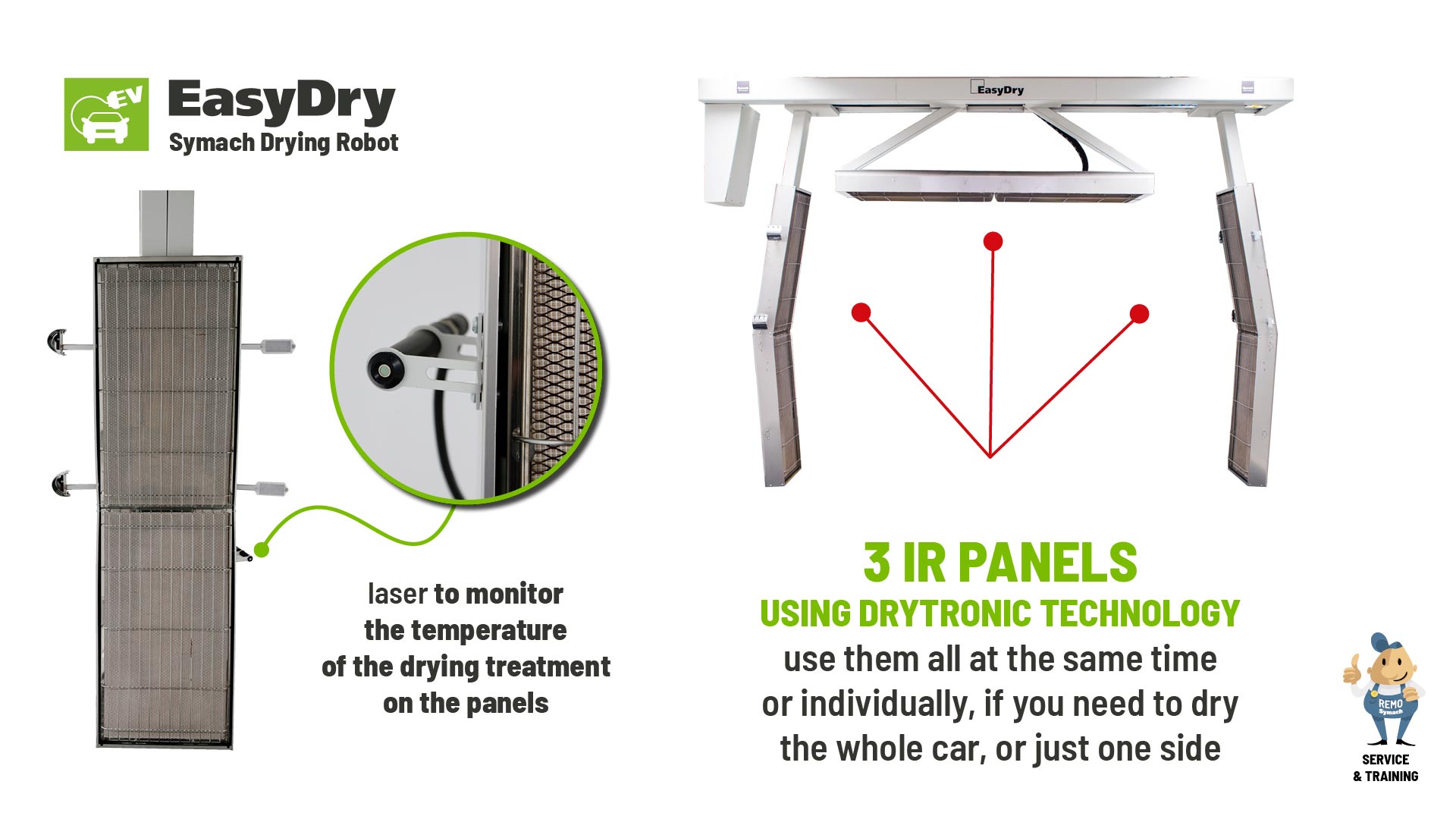

Its primary function is to efficiently dry waterborne/solvent basecoat and clear coats by means of infrared waves generated using the Drytronic Technology.

HOW IS COMPOSED THE EASYDRY DRYING ROBOT FOR SPRAYBOOTH

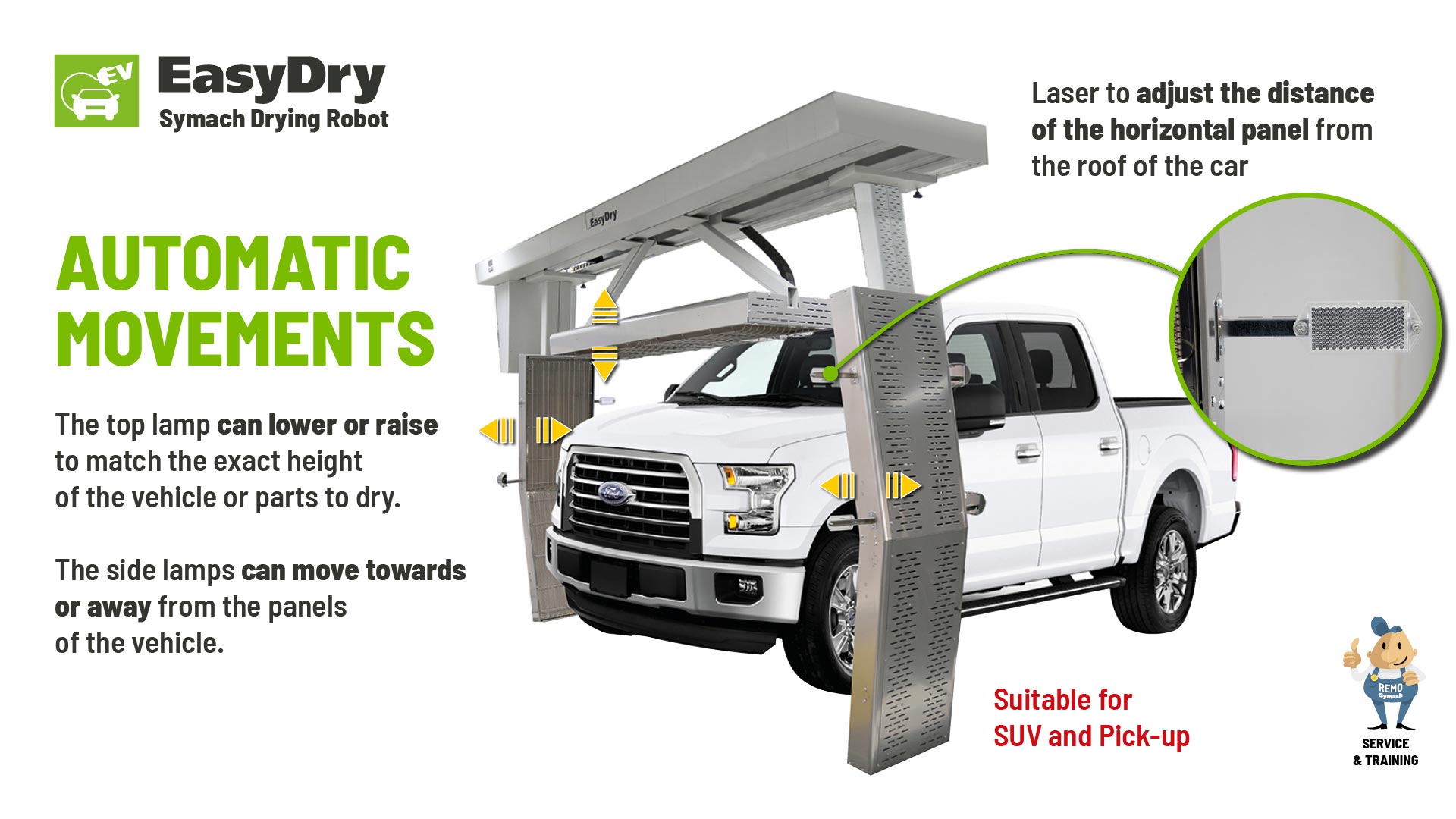

The EasyDry drying robot comprises an overhead crane and three sets of radiant panels, allowing it to employ infrared radiant waves on all sides of the vehicle as well as parts on stands. The horizontal set of radiant panels adjusts automatically, moving up and down to achieve the ideal distance and conform to the vehicle’s shape and spare parts. It traverses the length of the spray booth, spreading DryTronic waves at a 180° angle across the painted vehicle’s surface.

Equipped with a built-in database, the EasyDry robot stores formulas for drying various automotive paint manufacturers’ waterborne/solvent basecoat and clear coat products. Technicians can select the desired brand and paint system, enabling the robot to autonomously manage the drying treatment by considering factors such as distance, color, paint thickness, and climate. A built-in laser constantly monitors and assesses the drying process’s quality, facilitating automatic adjustments and control of the treatment.

Discover our wide range of bodyshop equipment and the FixLine system.